Automotive: heating solutions for an innovative industry

Whether inside the vehicle or on its outside, the range of applications for heating plates and cooling plates in the automotive sector is wide. Busse is a listed ancillary equipment supplier complete with D-U-N-S number.

In addition, all our products fulfil the requirements of ISO 9000, which is important for the automotive industry.

Optimal solutions for vehicle manufacturers

The requirements in vehicle construction are high: a homogeneous temperature distribution combined with a high degree of heating plate evenness, a long service life, and product sizes up to 9.2 by 2.8 metres. We know these requirements and we meet them.

Perfectly tuned

Cars are a passion that many of us share. In addition to our passion for the automotive domain, we at Busse also have the appropriate expertise for enhancing important processes in vehicle manufacturing. Whether for laminating, forming, bonding or pressing, we always have the optimal solution at hand for our customers in automobile construction.

Heating and cooling plates are essential in vehicle construction. They are used for the production of technical textiles and moulded parts in vehicle interiors as well as on the exterior.

Here’s a concrete example: the particular product, for example the boot lining, initially exists in the form of sheet material. This sheet is heated with a press. And in this press are heating plates from Busse. When warm, the material can then be worked into its final shape.

Heating and cooling plates

Tomorrow's challenges

The automotive industry will change substantially over the coming decades.

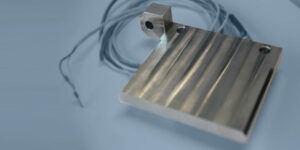

The transformation to e-mobility is already noticeably in progress. Busse also has products ready for this innovative field. Our heating plates, for example, can be used to test battery cooling systems.

In this case, Busse heating plates simulate the heat emitted by the batteries.

Aluminium welded constructions are part of the central range of services from Busse. We produce individual solutions according to your specific requirements.

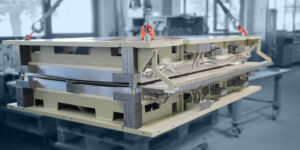

We manufacture prototype, pre-series and series tools for a wide range of manufacturing technologies. Depending on the component geometry to be produced, the number of pieces and the individual specifications, we develop a suitable tool concept that best suits your requirements from a technical and economic perspective.

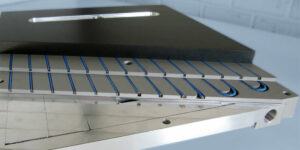

Very exact temperatures are achieved at the plate surface with maximum precision through the circulation of liquids such as thermal oil or water inside the plate. Medium plates can be used for both surface heating and cooling.

Hybrid heating plates combine the best features of two worlds: the speed of electric heating and the homogeneous temperature control provided by a liquid heating medium. In addition, these heating plates allow a precise control of the temperature.

Aluminium electric heating plates are true all-rounders and are suitable for a wide variety of demanding applications. In the laboratory, for instance, in open-cast mining, or in automotive manufacturing. They are manufactured in sandwich construction from aluminium sheets equipped with a heating conductor system.

Cases

From heating and cooling plates, heating tables and tools to cooling tunnels and aluminium charging trays measuring 9.2 x 2.8 metres – whatever you have in mind, together we’ll develop a heating or cooling solution for your project that is tailored to your needs.