Competent support right from the start

Busse Heizplattentechnik stands for problem-solving expertise and top performance at all levels: in advice and consulting, project planning, production, delivery, assembly and installation, and service. Give us a call – our experienced service team will be happy to help you with advice and practical support.

Always there for you: our repair service

Our mission is to ensure maximum machine availability and to extend the service life of your heating plates. In our repair service, we therefore act quickly, flexibly, and always reliably.

Your heating plate –

repaired in 6 hours!

You're in the middle of veneering work and your heating plate fails or it refuses to work reliably? Our lightning-fast 6-hour service will help you straight away. Here's an example: if you come to us early in the morning with the defective heating plate, you can already take the fully repaired hotplate back with you in the afternoon. In terms of its electrics, your heating plate will then be as good as new again. If you're not in a hurry, you can of course also send the equipment to us through a forwarding agent.

Electrically defective heating plates can usually always be repaired. In the case of mechanical damage, however, the repair is much more complicated. A complete replacement of the heating plate is often unavoidable as the repair costs often exceed the new price. In such an event, we can provide you with the right heating plate for your application.

Competent support right from the start

Busse Heizplattentechnik stands for problem-solving expertise and top performance at all levels: in advice and consulting, project planning, production, delivery, assembly and installation, and service. Give us a call – our experienced service team will be happy to help you with advice and practical support.

Busse microstats

For our microstats we rely exclusively on devices from proven German manufacturers. These capillary tube measuring systems are optimally suited for panel mounting – both for 80 mm and 60 mm cut-outs. The frontal placement of the setpoint adjustment allows a simple and time-saving setting of the desired value. The microstat also offers another decisive advantage: no additional auxiliary energy is needed for temperature measurement.

Busse microprocessor controllers

Compared to the capillary tube controllers, the microprocessor controller achieves a much more accurate temperature measurement, namely +/- 1 degree. The measurement is made by PT-100 remote-reading resistance thermometers, which are separately available. Replacement costs are low because two separately interchangeable products are used. This is efficient because in the first instance it is often only the supply line of the measuring probes that is damaged.

Busse Mylar foil

This foil protects the heating plate surface and has a glue-repellent function. The product can be retrofitted on all heating plates. The Mylar foil is a biaxially oriented polyester film ("boPET") made of polyethylene terephthalate from DuPont. It has special properties thanks to a stretching process. The Mylar foil stands out in particular because of its high tensile strength, chemical, mechanical and thermal stability, and transparency. Compared to the standard surface of a heating plate, the foil is easier to clean of any glue residues. We have the foil in stock in a standard width of 1,500 mm for all common veneer presses. The cut length is calculated from the length of the heating plate plus 100 mm. Another advantage is the easy mounting of the foil: the aluminium profiles of the insulating pressure plate are used to clamp the foil.

Reverse engineering –

digitisation of components

With the help of reverse engineering, Busse generates complex CAD files for a wide variety of components and reproduces individual parts and small series. This saves you a lot of time and money for new designs.

Reverse engineering is an indispensable and increasingly popular method for creating a 3D model of components for which no CAD data or drawings are yet available. Classic designs are reconstructed and new developments are introduced. In this way, Busse can recover lost or missing design documents and update or even completely recreate as-built documentation.

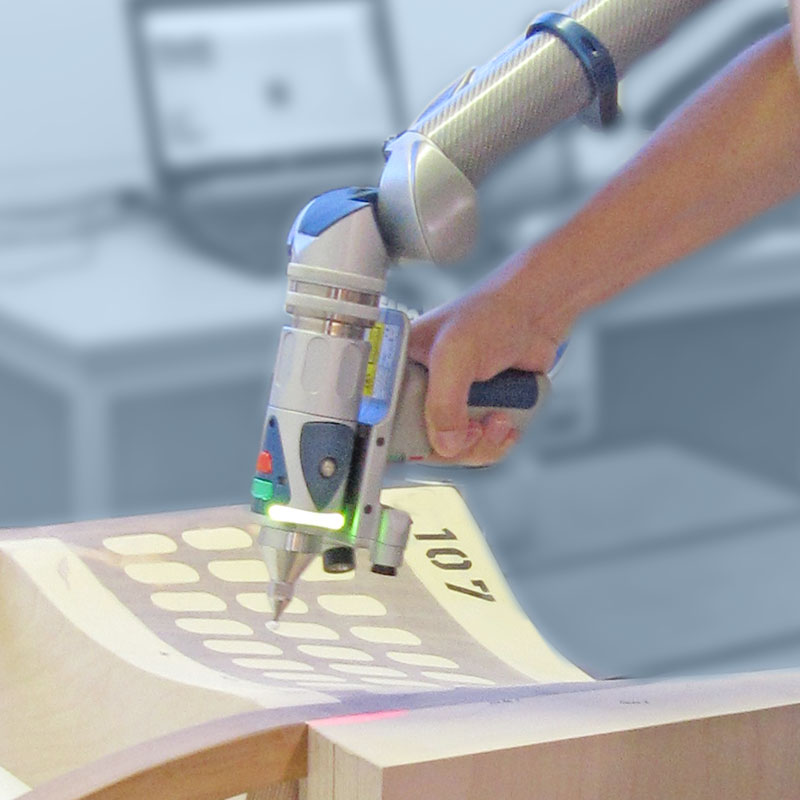

This is how we proceed at Busse: we use a non-contact 3D laser scanning system for the reverse engineering workflow. In this way, we implement the 3D modelling processes in just a single step. Using reverse engineering software, we can then supply you with complex CAD data in almost any desired file format.

Laser scanning is carried out both as part of the complete tool production process and as a pure service. We can scan and manufacture worn individual parts for you or reproduce them as small series.

Always up to date. Available all the time.

You can find everything you need to know about our products here – available for download with just one click. If you cannot find the information you are looking for, we would be happy to put together the relevant documents for you.

Just give us a call at +49.5772.9775-0 or contact us by e-mail.