Specials

Aluminium welded constructions are part of the central range of Busse services, alongside toolmaking and heating plate production. We produce individual solutions and special machines according to your specific requirements.

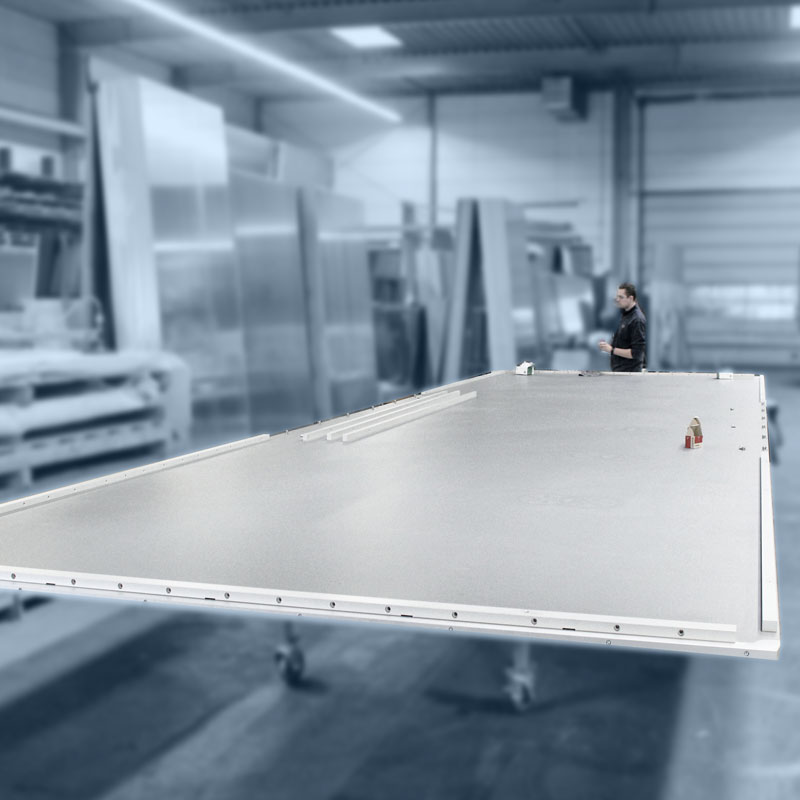

Aluminium construction

A company that processes 300 metric tons of aluminium each year knows what matters: flexibility for our customers is something that is particularly important to us.

Milled parts in the upper size range are our speciality. We set the highest quality standards in this area: with over a dozen CNC-controlled cutting machines and high-performance welding workstations, we manufacture high-precision aluminium products from a single source. Our experienced employees carry out the manual welding work using modern suction technology on completely level tables – always safely, efficiently, and tailored to your specific requirements.

In addition to individual and customised products, we also put together complete assemblies for our customers. Several heating presses enable us to manufacture large-area tray constructions using adhesive technology under the influence of pressure and temperature. Even huge aluminium feeding trays with dimensions of 17,000 x 4,000 mm, for example for car body panels in vehicle construction, are no problem for us.

Tool construction

We manufacture prototype, pre-series and series production tools for a variety of manufacturing technologies. Depending on the component geometry to be produced, the number of units and the individual specifications, we develop a suitable tool concept that best suits your requirements from a technical and economic point of view.

- Everything from a single source: engineering, surface scanning and reconstruction, design, machining, temperature control, in-house prototyping

- Press tools with multiplex support mould

- Aluminium press tools

- Steel press tools

- Flexible heating plates

Multiplex press tools

Busse produces economical press tools made of multiplex or beech plywood. Their construction consists of an unheated, stretch-free support form. All tools are also available with extensive accessories on request.

Features:

- Suitable for press thicknesses smaller than 30 mm

- 10 to 12 mm thick electric heating plate with insulating intermediate layer

- Moulded multi-storey heating plates possible

- Maximum temperature: 95 °C

- Maximum pressure: 25 kg/cm²

- Can be used in production using high-frequency technology

Advantages:

- No punctures if the residual moisture is too high

- Even temperature distribution

- Only the heating plate - not the entire mould mass - is heated

- Short lead times

- Low emissions

- Minimal heat losses

- separate temperature control of upper and lower mould possible

- Cost-effective and fast production

- Production of a support mould on request

Aluminium press tools

For long tool life, short working cycles and strong 3D moulding deformations, we recommend tools made of aluminium. Whether unheated, with electric heating or heated by liquid media, Busse offers you the right solution for your needs.

Features:

- High-strength aluminium alloy

- Unheated

- Electrically heated

- Heated by liquid heat transfer media

Advantages:

- Long service life for high quantities

- Practically unlimited durability

- Shorter cycle times due to suitability for higher temperatures

- Heavy-duty 3D moulding possible

- Maximum pressure: 50 kg/cm2

Steel press tools

Steel tools from Busse are ideal for use in the production of Festholz® or Pagholz® parts. They stand out on account of their impressive quality and particularly long service life.

Features:

- Electric or heat transfer heating

- Chrome plating and etching of the surface structure possible

- Very high compression of the veneer layers

Advantages:

- Maximum operating temperature: 250 °C

- Maximum pressure: 150 kg/cm²

- Very long service life

- Increase of production efficiency thanks to integrated pinching edge

Control cabinet construction

Optimally matched to our heating plate and to your requirements:

the temperature control system from Busse. From a simple capillary tube controller to a control cabinet with PLC connection. Our commitment is to supply you with the best possible heating plate solution. To make sure your heating plates operate reliably and efficiently, we also manufacture the appropriate temperature control system for you.

Special machines

Optimally matched to our heating plate and to your requirements:

the temperature control system from Busse. From a simple capillary tube controller to a control cabinet with PLC connection. Our commitment is to supply you with the best possible heating plate solution. To make sure your heating plates operate reliably and efficiently, we also manufacture the appropriate temperature control system for you.